Project Description

/details

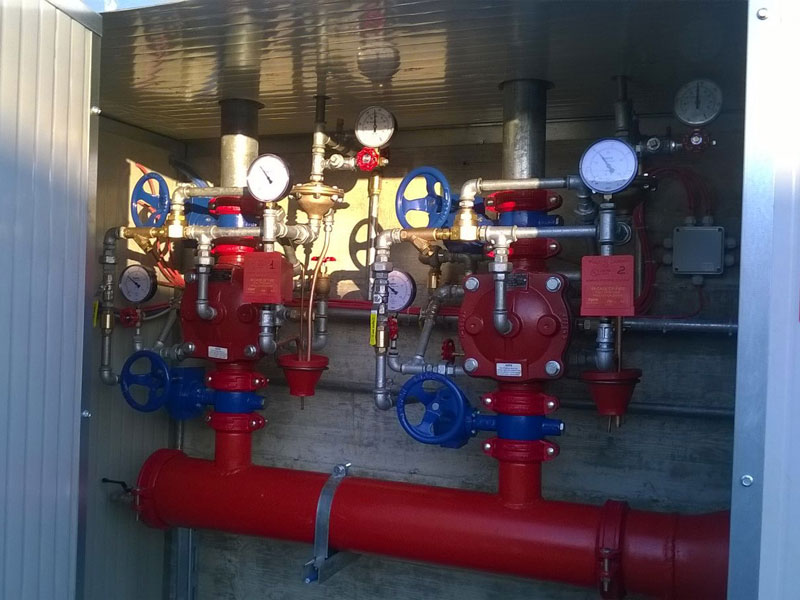

Castagna Antincendi manufacture deluge cooling systems of any type; the deluge system is a fixed fire protection system that completely soaks the area with water under pressure through a system of pipes and open sprinkler discharge heads.

The pipes are empty and remain so until the deluge valve is activated through an activation system that can be hydraulic, pneumatic or electric.

Deluge systems are normally used to protect high risk areas through the formation of water barriers which, cooling, prevent structures from deforming and collapsing.

Deluge valves prevent water from entering the pipes until the entire system is activated.

They are kept closed by the pressurised chamber (diaphragm chamber) associated with the valve itself. The pressure inside is maintained in its turn by means of a restriction on the loading line. This chamber is also connected to the detection line, whatever the type.

When the pressure drops in the upper chamber of the valve through the detection line, the clapet valve rises due to the pressure of the water present under the valve itself.

At this point the water comes out and reaches the network of nozzles, flooding the object or area that needs protecting, also activating the acoustic alarm.

Deluge systems can also be activated manually by means of a command located on board the valve or remotely.

/applications

Chemical and pharmaceutical industry; storehouses of easily flammable substances; areas where fire spreads rapidly; tanks containing combustible solutions; power transformers; conveyor belts; underground or closed cable ways; pumps and compressors for flammable liquids; compartmentalisation of large storehouses; oil tanks; metal structures exposed to fire.

/advantages

Effective on very high risks

Intervenes on the entire protected area

Coded total prefabrication

Zero environmental impact

Maximum safety for the people inside

No visibility problem during and after a discharge

Quick installation thanks to the prefabricated system

Special Applications

Available according to NFPA and FM Global standards

/advantages

Effective on very high risks

Intervenes on the entire protected area

Coded total prefabrication

Zero environmental impact

Maximum safety for the people inside

No visibility problem during and after a discharge

Quick installation thanks to the prefabricated system

Special Applications

Available according to NFPA and FM Global standards

/details

Castagna Antincendi manufacture deluge cooling systems of any type; the deluge system is a fixed fire protection system that completely soaks the area with water under pressure through a system of pipes and open sprinkler discharge heads.

The pipes are empty and remain so until the deluge valve is activated through an activation system that can be hydraulic, pneumatic or electric.

Deluge systems are normally used to protect high risk areas through the formation of water barriers which, cooling, prevent structures from deforming and collapsing.

Deluge valves prevent water from entering the pipes until the entire system is activated.

They are kept closed by the pressurised chamber (diaphragm chamber) associated with the valve itself. The pressure inside is maintained in its turn by means of a restriction on the loading line. This chamber is also connected to the detection line, whatever the type.

When the pressure drops in the upper chamber of the valve through the detection line, the clapet valve rises due to the pressure of the water present under the valve itself.

At this point the water comes out and reaches the network of nozzles, flooding the object or area that needs protecting, also activating the acoustic alarm.

Deluge systems can also be activated manually by means of a command located on board the valve or remotely.

/applications

Chemical and pharmaceutical industry; storehouses of easily flammable substances; areas where fire spreads rapidly; tanks containing combustible solutions; power transformers; conveyor belts; underground or closed cable ways; pumps and compressors for flammable liquids; compartmentalisation of large storehouses; oil tanks; metal structures exposed to fire.