Project Description

/details

SENTINELLA® fire extinguishing system for painting booths

RELIABLE, SIMPLE AND FAST, IT’S GREAT!

We often encounter high likelihoods of fire risk inside surface finishing plants; the causes of fire in painting plants are mainly due to an accumulation of charges on the electrostatic spray guns, the presence of a potentially explosive atmosphere due to the presence of flammable vapours or solvents, ineffective grounding or dust deposits inside filters and cyclone units.

The high level of automation in painting increases the risk of fire. If the ignition sources are not detected at the origin and stamped out at an early stage, the result can be a devastating fire.

Not locating and putting out a painting booth fire may put workers’ health at risk, result in loss of the machinery, the adjacent machines or even the entire building.

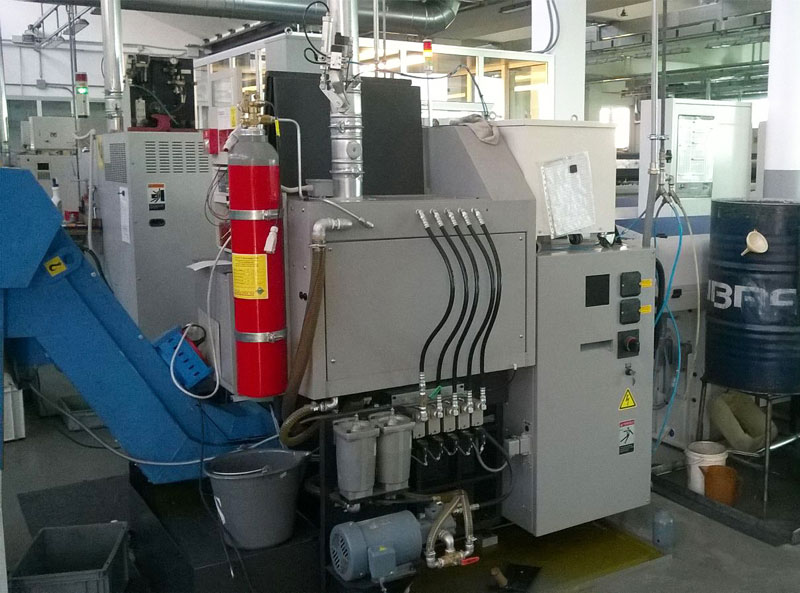

Thanks to their know-how and the number of SENTINELLA® fire extinguishing systems they have installed worldwide, Castagna Antincendi have developed an automatic CO2 fire protection system for painting booths that guarantees protection during all stages of the painting process.

The SENTINELLA® CO2 fire extinguishing system is a modular system built ad hoc for your machinery; it can be completely customised according to customer requirements. In alternative to the CO2 extinguishing system, in specific cases such as booths and processes with operators working inside, we offer extinguishing solutions involving chemical and inert gases, extinguishing powder, foam, water-foam, sprinklers and water mist.

In our over 40 years of experience we have installed hundreds of SENTINELLA® fire extinguishing systems and numerous painting system manufacturers have already chosen us as partner.

SENTINELLA® is a fire protection system born, developed and tested for painting booths and systems that fully meets the most restrictive safety standards required by the Machinery Directive 2006/42/EC.

With our SENTINELLA® fire extinguishing system it is possible to minimise the risks and high costs deriving from accidents and lost production; all that’s left for you to do is concentrate on production.

/applications

Fire protection system born and developed for painting systems and booths, oven booths, liquid spray painting, pre-treatment systems, painting lines, powder spray painting booths, solvent spray booths, water spray booths, vertical booths, robotic washing systems, painting tunnels, manual spray booths, UV-curing painting systems, automotive painting booths.

/advantages

Timeliness of intervention, limiting damage to a minimum

24/7 protection even when no operator is present

No halts in production

After-sales assistance

Easy to restore after use

Very high safety

Integration with the machinery’s PLC

Modular system adaptable to your needs

Available in KITS

Minimum maintenance

Independent fire extinguishing system

Refilling is simple and inexpensive

Fully complies with the Machinery Directive 2006/42/EC

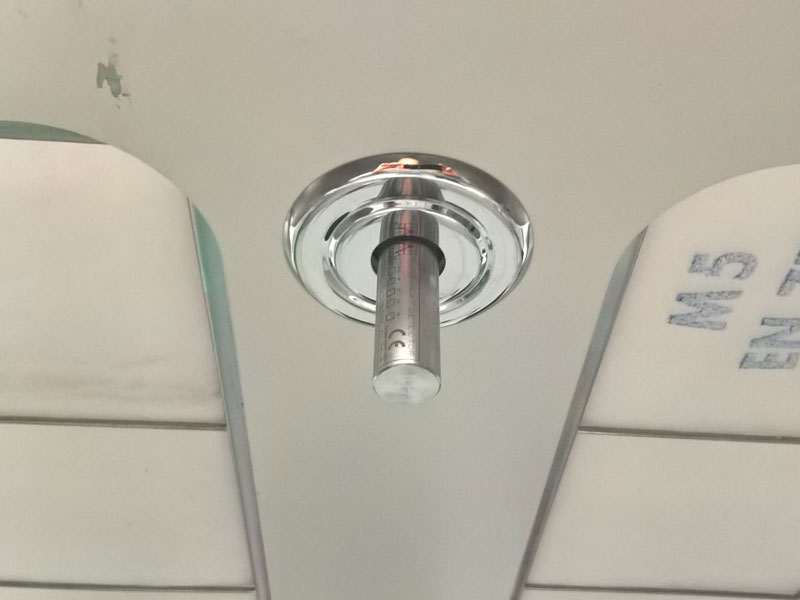

Advice on appropriate detection system (thermal, UV/IR flame, spark)

Available according to CE, UNI EN 13478; EN 12215; EN 50174; EN 12981; EN ISO 13849, NFPA and FM standards.

Customisation of suppression solutions

ATEX (on request)

Specialised support

/advantages

Timeliness of intervention, limiting damage to a minimum

24/7 protection even when no operator is present

No halts in production

After-sales assistance

Easy to restore after use

Very high safety

Integration with the machinery’s PLC

Modular system adaptable to your needs

Available in KITS

Minimum maintenance

Independent fire extinguishing system

Refilling is simple and inexpensive

Fully complies with the Machinery Directive 2006/42/EC

Advice on appropriate detection system (thermal, UV/IR flame, spark)

Available according to CE, UNI EN 13478; EN 12215; EN 50174; EN 12981; EN ISO 13849, NFPA and FM standards.

Customisation of suppression solutions

ATEX (on request)

Specialised support

/details

SENTINELLA® fire extinguishing system for painting booths

RELIABLE, SIMPLE AND FAST, IT’S GREAT!

We often encounter high likelihoods of fire risk inside surface finishing plants; the causes of fire in painting plants are mainly due to an accumulation of charges on the electrostatic spray guns, the presence of a potentially explosive atmosphere due to the presence of flammable vapours or solvents, ineffective grounding or dust deposits inside filters and cyclone units.

The high level of automation in painting increases the risk of fire. If the ignition sources are not detected at the origin and stamped out at an early stage, the result can be a devastating fire.

Not locating and putting out a painting booth fire may put workers’ health at risk, result in loss of the machinery, the adjacent machines or even the entire building.

Thanks to their know-how and the number of SENTINELLA® fire extinguishing systems they have installed worldwide, Castagna Antincendi have developed an automatic CO2 fire protection system for painting booths that guarantees protection during all stages of the painting process.

The SENTINELLA® CO2 fire extinguishing system is a modular system built ad hoc for your machinery; it can be completely customised according to customer requirements. In alternative to the CO2 extinguishing system, in specific cases such as booths and processes with operators working inside, we offer extinguishing solutions involving chemical and inert gases, extinguishing powder, foam, water-foam, sprinklers and water mist.

In our over 40 years of experience we have installed hundreds of SENTINELLA® fire extinguishing systems and numerous painting system manufacturers have already chosen us as partner.

SENTINELLA® is a fire protection system born, developed and tested for painting booths and systems that fully meets the most restrictive safety standards required by the Machinery Directive 2006/42/EC.

With our SENTINELLA® fire extinguishing system it is possible to minimise the risks and high costs deriving from accidents and lost production; all that’s left for you to do is concentrate on production.

/applications

Fire protection system born and developed for painting systems and booths, oven booths, liquid spray painting, pre-treatment systems, painting lines, powder spray painting booths, solvent spray booths, water spray booths, vertical booths, robotic washing systems, painting tunnels, manual spray booths, UV-curing painting systems, automotive painting booths.